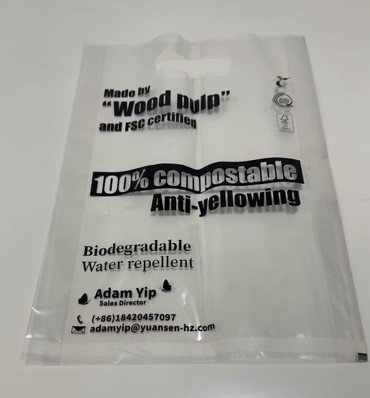

At Conxnect, we're committed to developing eco-friendly material alternatives that reduce environmental impact without compromising on performance. Our Green and Biodegradable Materials are designed for businesses looking to improve their sustainability practices.

Our materials are developed through extensive research and testing, ensuring they meet industry standards while offering biodegradable and compostable properties.

In replacing all other plastic sticker or shrink wrapping but in the market

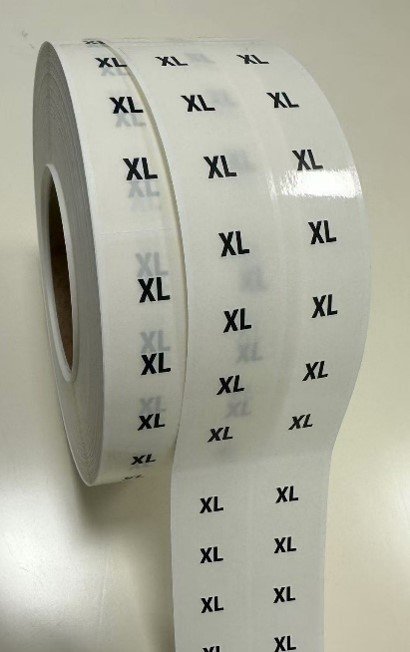

Specially made in replacing cellulose kind of other plastic label and to direct apply to textile items

Face composition: degradable cellulose film (Din Certco certification)

Weight: 30g/m² ± 10%

Thickness: 0.023mm ± 10%

A general purposed permanent, acrylic emulsion adhesive. It does not contain APEO which is hazardous chemical commonly found in garment manufacturing process.

A white glassine paper with excellent roll label converting properties.

Weight: 55g/m² ± 10%

Thickness: 0.053mm ± 10%

Available thickness: 23, 35, 45, 60μm

Temperature resistance: 120℃

Appearance: no 100% clear

Available thickness: 25, 35, 45μm

Temperature resistance: 55℃

Appearance: almost 100% clear (perform better as shrink wrapping material)

Our materials offer significant advantages for companies looking to reduce their environmental impact

Our materials naturally decompose in composting conditions without leaving harmful residues, reducing landfill waste.

Made from plant-based materials that can be regrown, reducing dependence on fossil fuel-derived plastics.

Free from hazardous chemicals like APEO, providing safer options for consumers and manufacturing workers.

Contact our team today to discuss your project requirements and how we can help you achieve your goals.

Contact Us